Say Goodbye to Normal Tire, NASA’s Airless ‘Superelastic Tire’ for Personal Vehicles Soon

NASA, the space agency best known for exploring other worlds, might soon change the way we drive on Earth. At its Glenn Research Center in Cleveland, Ohio, engineers have spent years developing a groundbreaking wheel technology designed for the extreme conditions of the Moon and Mars. Now, that same technology, the Superelastic Tire, could redefine tires for bicycles, cars, and even heavy-duty vehicles right here at home.

The Origin: Tires Built for Space Exploration

When NASA began planning long-term missions to the Moon and Mars, it faced an unusual engineering challenge: how to build a tire that could survive environments far harsher than Earth’s. On other planets, extreme temperatures, sharp rocks, and the absence of air make traditional rubber tires impractical. Even minor punctures could destroy a mission.

To overcome this, NASA’s Glenn Research Center, in partnership with the Goodyear Tire and Rubber Company, developed an entirely new kind of tire made not from rubber, but from shape memory alloys (SMAs). These are special metallic materials that can be bent, twisted, and deformed, yet return to their original shape without permanent damage.

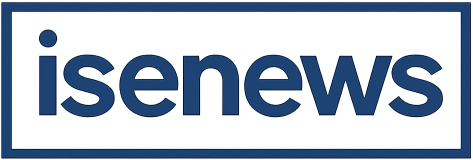

The result was the Superelastic Tire, a wheel that doesn’t need air, cannot go flat, and can endure immense stress without failing. It was originally tested for NASA’s Lunar Roving Vehicle and later for potential use in Mars rovers, capable of rolling over rocks, sand, and steep inclines without ever bursting or losing traction.

The Science Behind the Superelastic Tire

The Superelastic Tire is made primarily from a nickel-titanium alloy, the same family of materials used in surgical stents and eyeglass frames that can bend and recover. This alloy exhibits a property called superelasticity, allowing it to deform under high strain and then revert to its exact original form when the force is removed.

Unlike conventional tires filled with pressurized air, these tires rely on the flexibility of the metal itself. Every coil and mesh structure in the tire absorbs shocks and adapts to terrain, providing a level of durability and traction that traditional tires can’t match.

In simple terms, it acts like a metal spring rather than a balloon. Even when crushed or bent under heavy weight, the tire rebounds instantly, no inflation required.

NASA researchers have demonstrated that these tires can withstand temperatures ranging from -100°C to +200°C, meaning they could perform in extreme cold or heat, from Martian frost to desert roads on Earth.

From Space Rovers to Earth Roads

After proving the tire’s reliability in space conditions, NASA began exploring how this technology could benefit people on Earth. The agency started licensing the Superelastic Tire design to commercial manufacturers for adaptation to consumer vehicles.

The goal is to build airless, puncture-proof, and maintenance-free tires for bicycles, cars, and possibly even industrial machinery. Imagine never having to check air pressure, patch a puncture, or replace a flat tire again.

Early prototypes for bicycles have already been tested, demonstrating excellent shock absorption and road performance. For automobiles, NASA engineers are collaborating with tire companies to create scalable versions capable of supporting higher speeds and heavier loads while maintaining fuel efficiency and comfort.

If commercialized, these tires could drastically reduce waste, eliminating millions of discarded rubber tires each year, and save drivers both money and time spent on maintenance.

Why Shape Memory Alloys Are a Game-Changer

Shape memory alloys are among the most advanced materials in modern engineering. They are lightweight, corrosion-resistant, and capable of undergoing large reversible deformations. When used in tire construction, they provide key advantages:

- No air, no punctures: Eliminating air chambers means no blowouts, leaks, or pressure loss.

- Longer lifespan: Metal mesh construction can last far longer than rubber tires, which degrade under sunlight and wear.

- Sustainability: Fewer replacements mean less environmental waste.

- Performance consistency: Tire pressure never changes, ensuring predictable handling and safety.

NASA’s engineers describe these materials as “near-indestructible” in space conditions — and that durability could translate into one of the most significant automotive advancements of the decade.

Challenges Before Mass Adoption

Despite its promise, the Superelastic Tire still faces hurdles before it becomes a standard on commercial roads. Scaling the technology for mass production is complex and costly. Nickel-titanium alloys are expensive to manufacture, and the specialized processes used by NASA must be adapted for high-volume output.

Another challenge lies in balancing flexibility with comfort. Metal tires behave differently from rubber, and engineers are still refining ways to ensure smooth, quiet rides at highway speeds.

Regulatory testing, road safety certification, and integration with existing vehicle systems are also essential before airless metallic tires can reach consumers. Yet, with growing interest from major manufacturers, these obstacles are being actively addressed.

The Future of Driving: A Blend of Space and Sustainability

The Superelastic Tire represents more than just an innovation in materials; it symbolizes the future of sustainable design. By merging aerospace research with Earth-based needs, NASA is showing how space technology can solve everyday problems.

As the world moves toward electric and autonomous vehicles, maintenance-free and energy-efficient tires could play a vital role in building cleaner, smarter transportation systems. Whether on lunar surfaces or suburban streets, the same technology may soon carry us forward.

A Space Innovation Rolling Into Daily Life

What started as a solution for astronauts and robotic explorers could soon benefit commuters, cyclists, and even delivery fleets. The Superelastic Tire bridges a powerful idea: the durability of space hardware meeting the practicality of modern mobility.

NASA’s engineers believe this could mark the beginning of a new era where flat tires become a thing of the past, not just for space missions, but for everyone on Earth.

First Appeared on

Source link